HAMMERHEAD CRANE

If you’re a bit short, why not buy a Mark 7 hammerhead (built in Portland Oregon) . Only $2450

When I teach my students about cranes i start off with a see saw.

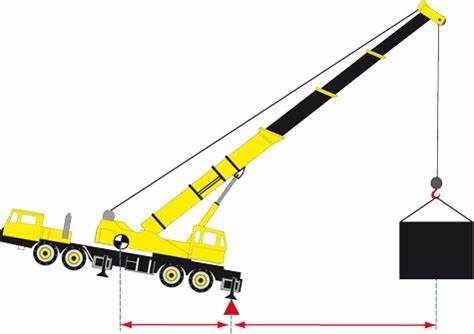

So just like with a see saw, a crane will tip over (or not) based on the TORQUE OR MOMENT. Weight times distance- that’s the basic formula.

The weight of the crane times the distance from the CG (center of gravity) to the fulcrum (the out rigger) gives us the torque or moment in inch pounds.

that’s all on1 side of the equation (the fulcrum) . On the other side we have the weight of the load and part of the boom (the part on the load side of the fulcrum) times its distance (from the CG) to the same fulcrum.

If the number on the crane side is greater, then the crane is stable. if the number on the load side is greater, then the crane could tip over

Let’s say 6ft times 50 pounds does not equal 6ft times 1 ton. Now how about a crane.

My hi-tech brake is a windlass with an added sprocket and a “dog”- a wooden arm that engages the sprocket.

I made a number of videos with Mateo, a high school student. Here he describes the parts of a hammerhead.

Mateo talks about measuring the distance from the CG of the load to the fulcrum. What’s the line of force? And what force are we talking about?

It’s the force of gravity which pulls everything straight down. This real force has an imaginary line going through the center of gravity of the load/crane/etc.

we measure the shortest distance between this line and the fulcrum. At time mark 1:44 I mis-spoke. The thin pipe sits atop the outrigger (which is where the crane pivots) – I should have had him position the pipe aligned with the CG of the load- the distance from line of force to the fulcrum is the 16″.

When he slews (swivels) the crane 90 degrees, it starts to tip over. How come? We haven’t changed the load – still 1 brick- and the trolley is the same distance out from the tower as before.

It’s the fulcrum. The fulcrum ( different outriggers) is closer to the CG of the crane and farther away from the CG of the load. And since torque/moment is weight x distance- when the distance increases- so does the moment.

I actually explained it better in the video above “tower crane outriggers-compute torque” at around time mark 0:30.

Mateo has to add a very heavy nut and bolt to prevent the crane tipping when it slews 90 degree.