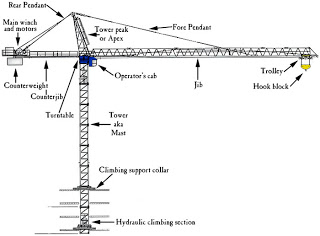

LUFFING JIB TOWER CRANE

The boom/jib can pivot up or down- that’s what luffing means. And the whole assembly can slew(rotate) at the top of the tower.

In my version the slewing ring (I use a heavy duty lazy susan) is at the base of the tower. To lift the load there’s a windlass ( the line wraps around the shaft which is connected to the blue wheel) and another windlass to “luff” the jib.

LUFFING JIB VS ” STANDARD “TOWER CRANE

Let’s say the job site is in an area with buildings on all sides. A regular tower crane might have a jib that’s 200 ft long, and maybe the distance between the buildings is only 50 ft. You need a crane that can fit in this tight space and still lift heavy loads.

You need a “luffer”. Look at the ones above. With the jib at a high angle, the working radius (how wide the jib and counter jib) might be as little as 20-30 ft.

In addition- the weight of the load is transferred more efficiently in a luffer than in a tower crane. Look at the tower crane above. Imagine that the load is almost at the end of the jib. All that weight will be transferred down the tower to the ground, but first it has to get from near the tip of the jib (?200ft?)

. Now go up and look at the luffer. The weight is transferred down the length of the jib and then down the tower to the ground. but the base of the jib is almost in line with the tower- this makes for an easier and more direct transfer of the weight.

A luffer can lift a lot more than a tower crane.

Here’s the latest version of a luffer.

Here’s a luffer I built a few years ago. I used 1×4 spruce instead of the 1/4″ plywood “erector set” system above.

Mateo will now “run the numbers”.-He’ll compute the torque of the tower and the ctwt. on 1 side of the pivot point and then the torque of the load and the boom. Will the crane tip over?

What will happen when we slew the crane 90 degrees?

Many crane accidents happen when the crane slews. You can see why now- when the distance changes, so does the torque and that can cause the crane to overturn.

What if we don’t have any extra bricks lying around- and we have to slew the load (still at 50 degree boom angle) and we don’t want it to tip?

Now it’s time to reeve (thread) the boom line through the axle of the windlass.

Finally we can now attach the jib.

So what is a “fly jib”?

When you connect the jib to the tower don’t forget there’s a top and a bottom. Mateo explains.

When erecting tower cranes, they have to bring in other cranes to lift the different parts. That includes setting the concrete slabs ( the counterweights) into slots in the counter jib.

I used my luffing jib tower crane to do the same thing.

Here’s a real world problem.

WHAT’S THE MAXIMUM LOAD YOU CAN LIFT WITH;

the jib @ 50 degrees

only 6 bricks for ct.wt.

adhering to a 1.5 Factor of Safety

continuing

So that’s how we got 9.34# for the max. load under these conditions.

How much more could we lift with 8 bricks for ct.wt?

Here’s another problem.

With a 6 brick ct.wt. and an 8# load, what’s the maximum DISTANCE we can place the load?

Did you spot the mistake?

If the jib is lowered to 39 degrees, then its distance from the fulcrum increases and so does its torque. It only amounted to around 10 inch pounds so we disregarded it.